Author: Carla Bartolomé, ITENE

As part of the transition to a more circular economy, where the value of products, materials and resources is retained in the economy for as long as possible, and where waste generation is minimised, the European Commission has focused on improving the current management of packaging waste due to its high volume and environmental impact.

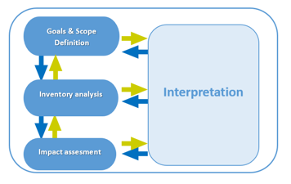

Therefore, the environmental sustainability of the enzymes production, enzymatic recycling processes and proofs of concepts developed within ENZYCLE, will be verified by performing a Life Cycle Assessment (LCA). LCA is an internationally standardised methodology (ISO 14040-ISO 14044), that helps to quantify the environmental impacts related to the production of goods and services. The LCA is divided into four stages:

(1) Definition of goal and scope,

(2) Life cycle inventory,

(3) Life Cycle Assessment and

(4) Life Cycle Interpretation.

The aim of developing the LCA in ENZYCLE is to quantitatively analyse the potential life cycle impacts of the new processes and solution developed against the current situation, the impossibility to recycle the material and its impacts to the environment.

In order to be as reliable as possible for the analysis, it is really important to correctly define the goal and scope of the study, identifying, the LCA’s purpose and the expected products of the study, determine the boundaries and assumptions based on the goal definition. LCA was born as a tool for analysis and comparison. However, the focus of an LCA is not the product in physical terms, but the service or function it performs. In order to compare different products or systems we must identify their function and be able to quantify it, which is know as functional unit (FU). The FU is the value from which all LCA calculations in the study will be referenced.

Another important consideration in the LCA is gathering the inventory data of the different processes and products that will be analysed. The LCA of a product must consider the inputs and outputs of all the stages of the life cycle: beginning with the raw materials extraction, followed by the manufacturing of the components, the use of the product, and finally its recycling or disposal as a waste. Transport, storage, distribution and other activities between stages of the life cycle, are included when having enough relevance. In accordance with the stages that are included in the LCA, there are different approaches defined:

- Cradle to gate: includes the extraction of raw materials, its distribution and manufacturing.

- Gate to gate: only considers the manufacturing of the product

- Gate to grave: includes the manufacturing of the product, client distribution, use and end of life.

- Cradle to grave: studies from the reconditioning of the raw materials to the waste management (recycling, disposal or other ways of waste management).

- Cradle-to-cradle: considers all the stages of the life cycle of the product. Beginning with the extraction of raw materials to the reintroduction of the product in the same manufacturing system or in other.

It is preferable that this information comes from primary sources, i.e. from the companies themselves. If this information is not available, existing official databases also contain reliable information.

With all this information, and the help of different softwares (such as Simapro), the impacts of the new processes and products can be calculated and compared to the current situation. Therefore, the benefits in the environment will be determined, and can be used as a tool for decision making in the companies.